FARHAT Ahmed

I’m a Mechanical Engineer,an Electrical Engineer,an Automation Engineer,a Robotics Lover

I’m a Mechanical Engineer,an Electrical Engineer,an Automation Engineer,a Robotics Lover

I am Farhat Ahmed, a special industrial machine manufacturer from Manouba, Tunisia. I have rich experience in Mechanical, Electrical and Automation, also I am good at Robotics.

Projects completed

Robot installed

Machine installed

Satisfied clients

Provide customized solutions to automate, optimize, and improve industrial processes.

Lorem ipsum dolor sit amet consectetuer adipiscing elit aenean commodo ligula eget.

Lorem ipsum dolor sit amet consectetuer adipiscing elit aenean commodo ligula eget.

Looking for a custom job? Click here to contact me! 👋

Bachelor of Science in Technology

Applied degree in electrical engineering, automation specialty

National Diploma of Engineer in Electromechanics, Specialty Mechatronics

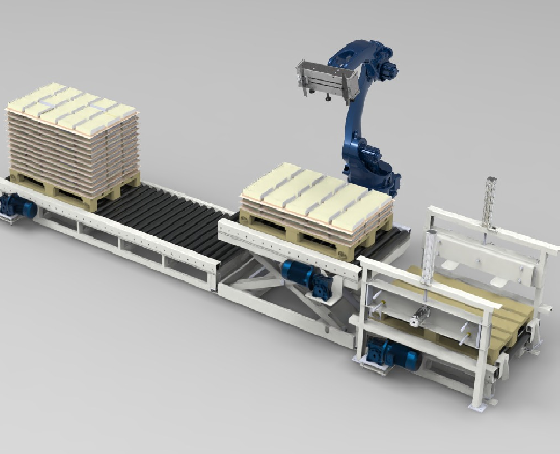

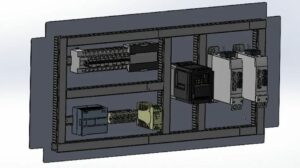

I am responsible for the design and manufacturing of custom-made special machines tailored to the specific needs of our company, while integrating robots into production lines to optimize efficiency and automation. My work involves creating technical solutions and implementing industrial robots to enhance productivity and precision in manufacturing processes.

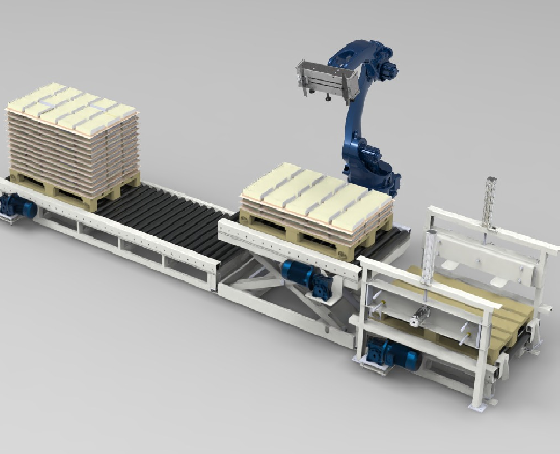

I have worked on a robotic depalletizing cell with 2D camera. I managed the project from start to finish, covering all aspects of electrical, mechanical, and automation systems. The project achieved a throughput of 700 products per hour, handling items weighing up to 500 grams.

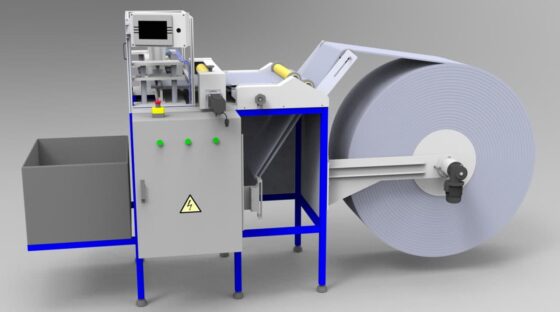

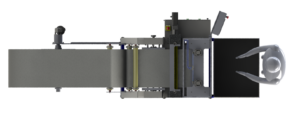

I made cutting machines specifically designed for foam paper, felt, and other paper types. These machines offer a cutting width range between 10 to 520 mm and can handle material thicknesses from 1 to 10 mm. I oversee the operation of these machines to ensure precise cutting, optimizing performance and productivity to meet the required output speeds and high-quality standards.

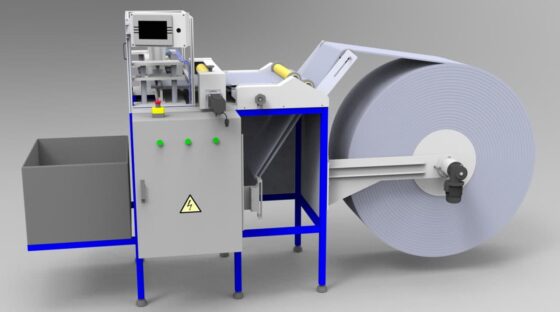

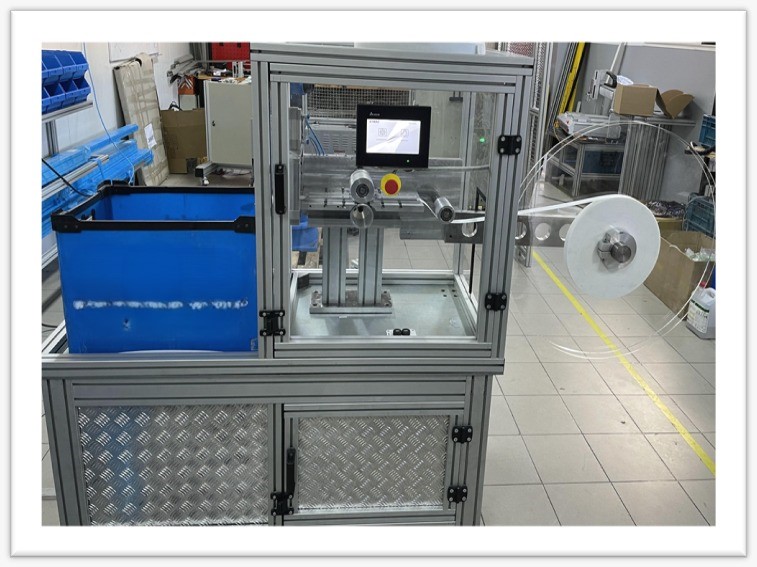

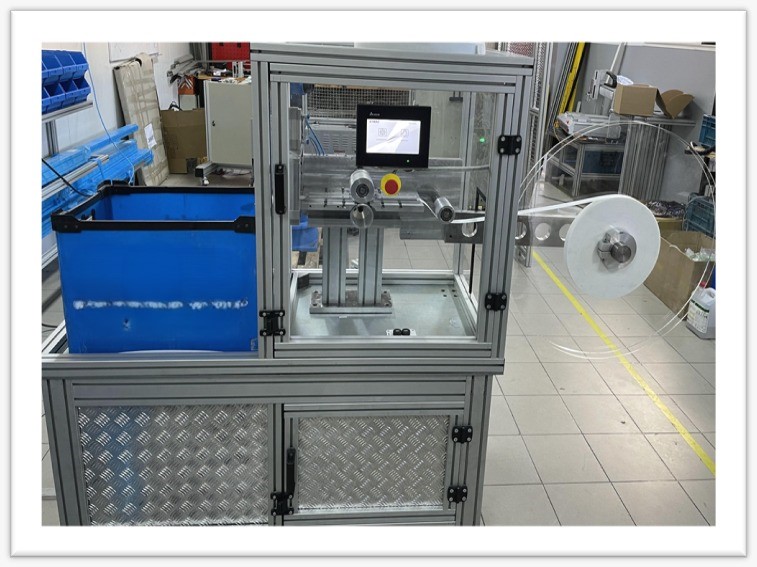

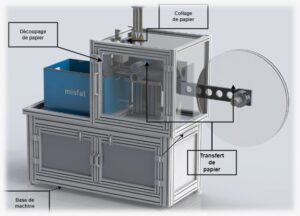

I made mini-cutting machines specifically designed for foam paper, felt, and other paper types. These machines offer a cutting width range between 10 to 110 mm and can handle material thicknesses from 1 to 10 mm. I oversee the operation of these machines to ensure precise cutting, optimizing performance and productivity to meet the required output speeds and high-quality standards.

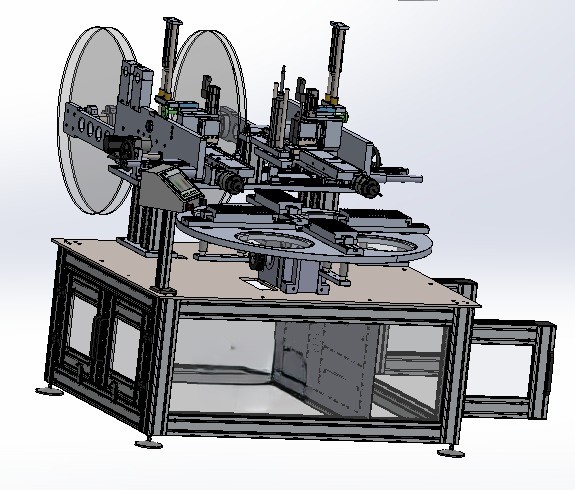

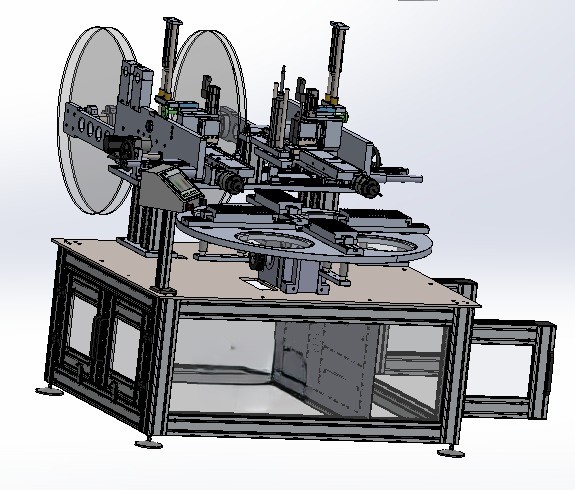

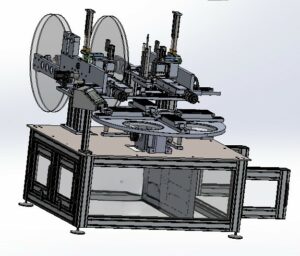

We have developed and manufactured three tape bonding machines specifically designed for the assembly of cabin filters. These machines are engineered to ensure maximum precision in tape application, guaranteeing consistent quality and high productivity. With advanced automation and ergonomic design, they can be easily integrated into existing production lines.

I have worked on a robotic depalletizing cell with 2D camera. I managed the project from start to finish, covering all aspects of electrical, mechanical, and automation systems. The project achieved a throughput of 700 products per hour, handling items weighing up to 500 grams.

This device is designed to mix pharmaceutical powders with precisely controlled speed and an optimized vibration system. Manufactured from stainless steel 316 to meet pharmaceutical standards, it features an advanced program for data collection and processing. Each batch is identified by a number or name, generating a detailed report to ensure traceability and compliance with audit requirements.

Training in SOLIDWORKS, Ladder Programming (TIA Portal), Electrical plan...

Email support

3D Design

2D Drafting

I enjoy working with the theme and learn so much. You guys make the process fun and interesting. Good luck! 👍

I enjoy working with the theme and learn so much. You guys make the process fun and interesting. Good luck! 🔥